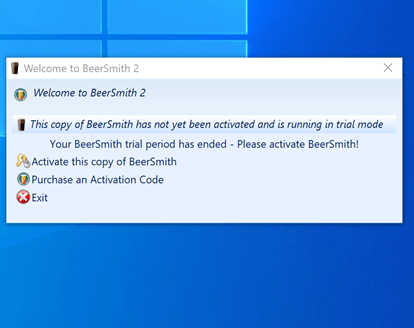

The other day, I tried to open my copy of BeerSmith 2 on my laptop, only to be greeted with this friendly message:

Nope, I was not running a trial version that required activation. I’ve owned and used this software since 2010 (back then just BeerSmith, and yeah I know there’s now a BeerSmith 3). It’s just been so long since I’ve opened the application that it logged me out.

To be honest, I don’t feel like trying to log back in. What’s my username? What’s my password? I could probably rotate through the 46,656 combinations of my most commonly used usernames and passwords and eventually get in, but then what would I find? Probably that I need to pay a renewal fee for what is now- like everything else digital in my life- a subscription-accessed Cloud-based service. Nah, fuck all that. We’re going analog.

Most of what I’ve brewed over the past three years have been variations on maybe half a handful of recipes. They’re all fairly simple, and they’re all written down in a notebook. Yes, these recipes were originally designed and developed- tweaked, revised, and updated- in the software. But I haven’t actually had BeerSmith running during a brew day in years.

All the more reason, when I sat down to put together a recipe for my system based on Dave Janssen’s research into Historical Grisette, it seemed absolutely absurd to go through all the trouble (and probable expense) of just logging back in. The malt and hop bills in Janssen’s Grisette are brilliantly simple; quite frankly I could probably nail most of it just by throwing a few things together based on his parameters and my knowledge of my system.

But, I want to do this right. I also want to free myself from this cumbersome, overly-complicated software with its clutter of unnecessary bells and whistles that I never use. To do that, I need to know what the software knows, so I set myself to the laborious task of researching: “Hey Google, how do I design a beer without software?” Ok, ProTip, computers are not good at telling you how to do things without the help of computers. Whether by oversight or by deliberate intent, Google missed the most important keyword in my query: “without!”

So, after scrolling past the multiple Ads for brewing software, I found the first twenty returned results all to be brewing software home pages, blog posts about brewing software, or HBT threads comparing/ contrasting brewing software or asking which is the best (or which is your favorite) brewing software. It wasn’t until the result deemed #21 in relevance by the search engine that I found any content actually relevant to my query: a blog post on an online homebrew retailer’s website. Luckily, this post contained a vital piece of information and my next point of departure: a picture of a book, a book that I own, Ray Daniels’ iconic Designing Great Beers. All this time I’ve had nearly all the knowledge I needed, in a book that my wife bought for me a dozen Christmases ago, forgotten and collecting dust on a shelf. She’s always a step ahead of me…

Most of the math that we are about to get into, I pulled from Designing Great Beers, but quite frankly what we’re looking at barely scratches the surface of that text. It’s definitely worth picking up. For our purposes here, we will be looking at four calculations, the things that until now I’ve relied on software to take care of for me:

- How to calculate your entire grain bill in pounds and ounces for each fermentable ingredient

- How to calculate your total water volume

- How to calculate your strike temps and volumes for single infusion and step infusion mash

- How to calculate your hop additions

Begin with the End in Mind:

Step one actually is exactly the same regardless of whether you are using software or doing your own math. Pick your beer style, then set your targets for:

- Batch size

- Original Gravity

- Final Gravity

- IBU

- ABV

- Color

You’ll also need to determine, based on your chosen beer style, a list of fermentable ingredients and their approximate ratio (as a percentage), as well as choose hop varieties.

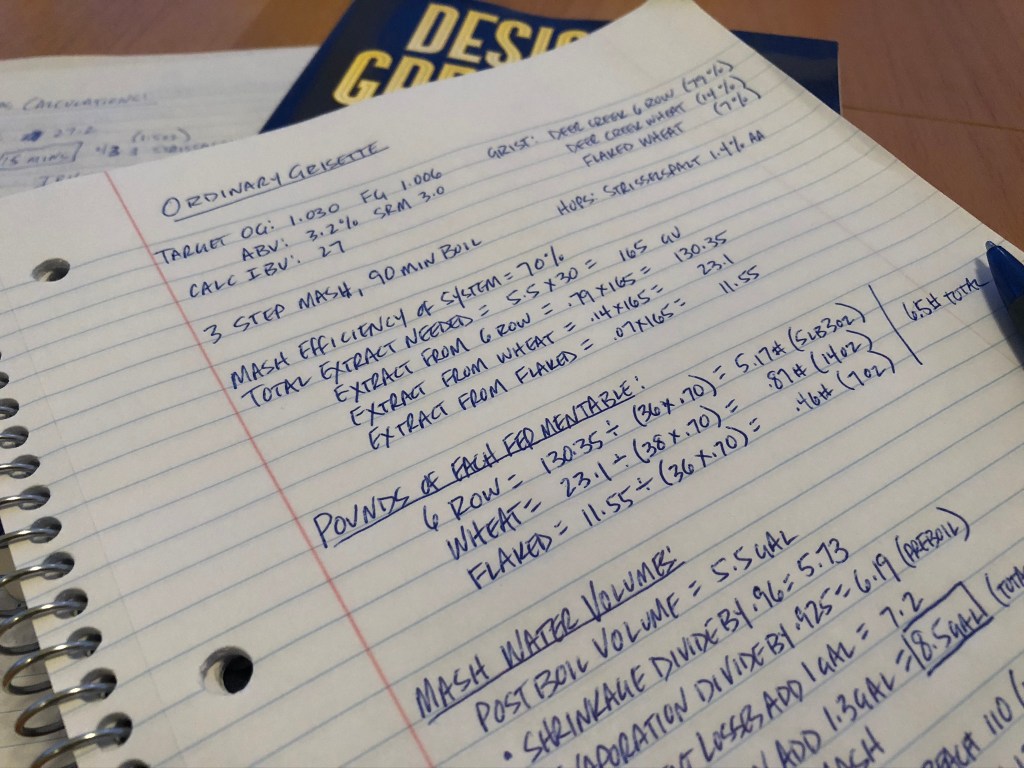

For my beer, which will be a Table Grisette, I have chosen Strisselspalt hops (1.4% AA) and the grist will be comprised of approx 79% local six-row pale malt, 14% local pale wheat, and 7% flaked wheat.

Batch size is 11.5 gallons (post boil volume), and I am targeting an OG of 1.026, FG of 1.006 (in reality probably a bit lower with my mixed culture) and about 23 IBUs from the Strisselspalt.

One note:

In most recipes, I target 10.5 gallons post boil to get 10 gallons into the fermenter. With the massive hop bill in this batch, I’m giving myself an extra gallon of post boil volume to ensure I get 10 gallons into the fermenter.

Calculate Grain Bill:

Now we’re ready to convert those percentages to pounds. We can do this in three steps:

1. Calculate the “total extract” needed from the mash. This is basically your target Original Gravity times batch size. In this equation, OG is expressed as Gravity Units (or GU) which is the last two or three digits (everything after the decimal) from your OG. In my example, I’m targeting an 11.5 gallon post-boil volume at 1.026 OG. So my GU would be 26, and the equation looks like this:

TOTAL EXTRACT = BATCH SIZE x GU

TOTAL EXTRACT = 11.5 x 26 =299

2. Calculate the extract needed from each component fermentable ingredient. This is simply the ingredient’s percentage (as a decimal) of the total grist times total extract calculated above. So . . .

INGREDIENT EXTRACT = INGREDIENT% x TOTAL EXTRACT

SIX ROW (79%) = 0.79 x 299 = 236.21

PALE WHEAT (14%) = 0.14 x 299 = 41.86

FLAKED WHEAT (7%) = 0.07 x 299 = 20.93

3. Convert extract to pounds for each fermentable ingredient. This is done by dividing the required extract of the ingredient (in GU, calculated above) by the potential extract of the ingredient (in GU) times the mash efficiency (as a decimal) of your system.

Potential extract is the gravity that can be derived from mashing one pound of a given grain in one gallon of water at 100% efficiency. For most base malts, that’s in the range of 1.035 – 1.040 and can typically be found on the spec sheet provided by the manufacturer. There is also a chart in Designing Great Beers that gives a general range for different malt types.

My mash efficiency is around 70%. So, to convert extract to pounds:

LBS = EXTRACT / (POTENTIAL EXTRACT x MASH EFFICIENCY)

SIX ROW = 236.21/ (36 x .70 )= 9.37 lbs= 9 lbs 6 oz

WHEAT = 41.86 / (38 x .70) = 1.57 lbs= 1 lb 9 oz

FLAKED WHEAT = 20.93 / (36 x .70) = 0.83 lbs= 13 oz

TOTAL GRAIN WEIGHT = 11.75 LBS

Calculate Water Volume:

Begin with your target post-boil volume. 11.5 gallons for our Grisette. We’ll need at least this much.

Next, add water to account for losses during the process. There are four areas during the process where water is lost:

- Shrinkage in Cooling – this equals 4% of post-boil volume, because science. Just divide by 0.96

- Evaporation during the boil – generally this occurs at a rate of 5% per hour. Divide by 0.95 for a 60 minute boil, or 0.925 for a 90 minute boil. If your evaporation rate is higher than 5% per hour, maybe back off on the heat a little, or adjust the formula to suit your system

- Equipment losses – this is water/ wort left in the HLT, in hoses and pumps, and under the false bottom of your mash tun at the end of runoff. It’s different for every system. On my system it’s virtually zero. We’ll use that number here. You should use whatever you’ve measured your equipment losses to be.

- Absorption in spent grains – there is a straight-forward formula for calculating this volume in gallons: Weight of total grist (in lbs) x 0.2 according to Daniels. Calculate that, and add to your total. (For whatever reason, after a few batches, I’ve found my absorption rate to be closer to .135, so that’s what I’ve used in the formula below).

So, for our Grisette:

- We start with our target volume of 11.5 gallons

- Divide by 0.96 = 12 gallons

- Divide 12 gal by 0.925 (90 min boil) = 13 gallons (this is our target pre-boil volume)

- Add 0 gallon for equipment losses = gallons

- Add (11.75 x 0.135 = 1.5 gallons) = 14.5 gallons total water needed

Calculate Strike Water temps and volumes:

Let’s start with a formula for calculating the strike water temp for dough in. If you’re doing a single infusion mash, this is all you’ll need. If you are doing a step infusion mash or using a mash out step, you’ll use this formula for dough in, plus a second formula below for the subsequent steps.

To get strike water temp, you’ll need to know your target mash temp, total grain weight, and desired water: grain ratio. A typical mash temp for single infusion (saccharification rest) is in the range of 149-160 depending on beer style and system. Water to grain ratio usually ranges from 1.25:1 to 1.5:1 but can go thicker or thinner depending on other factors. We will be doughing in low on our Grisette (110 initial infusion) with a water to grain ratio of 1.34:1.

Here’s the formula for strike temp on our initial infusion:

STRIKE TEMP = (0.2/RATIO)(TARGET MASH TEMP-INITIAL GRAIN TEMP)+TARGET MASH TEMP

STRIKE TEMP = (0.2/1.34)(110-78)+110 = 116

So, for our initial infusion, we will add 4 gallons of 116f water to our 11.75 lbs grain to reach an initial mash temp of 110f. This will be a 10 minute rest, followed by a second infusion to raise the mash to 128.

Here’s how we’ll know how much water to add for our second infusion:

SV = (TT – CT)(0.2*GW + WV) / (ST – TT)

Yeah, that’s a lot of abbreviation to keep the formula clean and short. Here’s the key:

SV = STRIKE WATER VOLUME

TT = TARGET MASH TEMP FOR YOUR NEXT STEP

CT = CURRENT MASH TEMP

GW = TOTAL WEIGHT OF GRAINS IN MASH

WV = TOTAL WATER CURRENTLY IN MASH (QTS)

ST = INFUSION STRIKE TEMP

TT = TARGET MASH TEMP FOR THIS STEP

Notice that with this equation, we are solving for water volume and need to decide on our strike temp. This is also how BeerSmith works. Honestly, with any step infusion mash I’ve done in the past, I use boiling water and round to the nearest .5 quart whatever the brewing software tells me to add. Anyway, here’s what the equation looks like for our Grisette:

SV = (TT – CT)(0.2*GW + TV) / (ST – TT)

SV = (128 – 110)(0.2*11.75 + 16) / (210 – 128)

SV = (18)(18.35) / (82) = 4 QTS

So, for our second infusion step, we add 1 gallon boiling water to raise our mash from 110 to 128. This is a 15 minute rest, followed by one more step to get the mash to our saccharification temp of 149. Same formula gets us there:

SV = (TT – CT)(0.2*GW + TV) / (ST – TT)

SV = (149 – 128)(0.2*11.75 + 20) / (210 – 149)

SV = (21)(22.35) / (61) = 7.69

For our third step, adding just under 2 gallons boiling water will get our 128f mash up to 149f. This is about a 50 minute rest, after which we fly sparge with the remaining water heated to 169. Since we’ve used a total of 7 gallons in our three step infusions, we have 7.5 gallons left of our original 14.5 gallon total that we’ll fly sparge with. Here’s our mash schedule:

Dough in with 4 gallons water at 118 to reach a mash temp of 110 (10 min rest)

Add 1 gallon boiling water to reach a mash temp of 128 (15 min rest)

Add 2 gallons boiling water to reach a mash temp of 149-151 (50 min rest)

Calculate Hop Additions:

Ok, we almost have our complete recipe. We just need to do a little more math to determine how much Strisselspalt we’ll add and at what point in the boil to attain our target IBUs.

For this exercise, we’ll need to know our desired IBU for our beer, as well as the alpha acid content of our hops. We’re targeting around 23 IBU, and our extremely low alpha acid Strisselspalt pellets clock in at 1.4% AA. We’ll also need to know the utilization % for whatever hop additions we’re using. This is commonly available information, and for our first wort, 60 and 15 min additions we can assume 34%, 30% and 15% utilization respectively. Finally, there is a gravity correction factor for beers over 1.050 OG, but as our Grisette is a modest 1.026, we won’t have to worry about that (the factor is set to 1 in our formula). So, two steps and two formulas:

For step one, we’ll calculate the IBU contribution of any late hop additions. That’s anything added between 29 and 0 minutes, sometimes called “character” or “flavor” or “aroma” hops. In our Grisette, that’s the 15 minute addition. We will add 4 ounces at this point, mostly for some flavor/ aroma contribution but they will also contribute some bitterness. We’ll need to find out what the bitterness contribution is so we can subtract that from our total to figure out our bittering hop additions at 60 mins and first wort. Here’s the formula for calculating the IBU contribution of 4 ounces at 15 mins:

IBU = OZ HOPS x UTILIZATION% x AA% x 7489

(POST BOIL VOLUME x GRAVITY CORRECTION)

IBU = 4 x .15 x .014 x 7489

(11.5 x 1)

IBU = 62.9 = 5.5 IBU

11.5

Since we’re getting 5.5 of our 23 IBU from our 15 minute “flavor” addition, our two bittering additions need to contribute about 17.5 IBU. We’ll add another 4 ounces at 60 minutes. Let’s calculate how much bitterness that will contribute:

IBU = OZ HOPS x UTILIZATION% x AA% x 7489

(POST BOIL VOLUME x GRAVITY CORRECTION)

IBU = 4 x .30 x .014 x 7489

(11.5 x 1)

IBU = 125.8 = 11 IBU

11.5

5.5 IBU from our 15 minute addition and 11 IBU at 60 mins= 16.5 of our 23 IBU total. Now let’s calculate how much Strisselspalt we’ll need to add in first wort hopping to make up the remaining 6.5 IBU:

OZ HOPS = POST BOIL VOLUME x GRAVITY CORRECTION x IBU

(UTILIZATION% x AA% x 7489)

OZ HOPS = 11.5 x 1 x 6.5

.34 x .014 x 7489

OZ HOPS = 74.75 = 2OZ

35.64

Hop Schedule for our Ordinary Grisette:

- FWH: 2 ounces Strisselspalt (1.4% AA) for 6.5 IBU

- 60 mins: 4 ounces Strisselspalt (1.4% AA) for 11 IBU

- 15 mins: 4 ounces Strisselspalt (1.4% AA) for 5.5 IBU

Putting it all Together:

We’ve now explored all four calculations we wanted to explore, and applied them to our Grisette. Here’s our basic recipe:

Ordinary Grisette

Target OG: 1.026 FG 1.006

Target ABV: 2.6% SRM 3.0

Calculated IBU: 23

3 Step Infusion Mash, 90 minute boil

Ingredients:

9 lbs 6 oz Deer Creek 6 Row Pale Malt (79%)

1 lb 9 oz Deer Creek Pale Wheat Malt (14%)

13 oz Flaked Wheat (7%)

10 oz Strisselspalt 1.4%AA (2 oz @ FWH, 4 oz @ 60 mins, 4 oz @ 15 mins)

Mash:

Dough in with 4 gallons 118f water to reach 110f mash temp (10 min b- glucan rest)

Add 1 gallon boiling water to reach 128f mash temp (15 min protein rest)

Add 2 gallons boiling water to reach 149-151f mash temp (50 min saccharification rest)

Fly sparge with 7.5 gallons 169f water to reach pre-boil volume of 13 gallons

90 Minute Boil:

Add 2 oz Strisselspalt at FWH (6.5 IBU)

Add 4 oz Strisselspalt at 60 mins (11 IBU)

Add 4 oz Strisselspalt at 15 mins (5.5 IBU)

Chill to pitching temp of 60-64 and transfer 10 gallons to fermenter.